-

IEC 60950 Clause 2.10.8.4 Harden Steel Pin Scratch Resistance Test Apparatus

-

IEC 60335-1 Insulation Surface Scratch Resistance Test Apparatus For Test Household Appliances

Working principle of Harden Steel Pin Scratch Resistance Test Apparatus:

The surface of the insulation is then scratched by means of a hardened steel pin, the end of which has the form of a cone with an angle of 40°. Its tip is rounded with a radius of 0,25 mm ± 0,02 mm. The pin is held at an angle of 80° to 85° to the horizontal and loaded so that the force exerted along its axis is 10 N ± 0,5 N. The scratches are made by drawing the pin along the surface of the insulation at a speed of approximately 20 mm/s. Two parallel scratches are made. They are spaced sufficiently apart so that they are not affected by each other, their length covering approximately 25 % of the length of the insulation. Two similar scratches are made at 90° to the first pair without crossing them.

Equipment characteristics:

This tester adopts PLC + touch screen control system and stepper motor drive, the scratch distance, scratch times and scratch speed can be preset on the touch screen. And it with a 90o auto-rotation test bench, so it is easy to realize the scratching test in both vertical and horizontal direction.

------------------------------------------------------------------------------------------

the below are the Standard compliant of these IEC 60950 AND IEC 60335 for the abrasion resistance test:

-

IEC 60950 Clause 2.10.8.4 Abrasion resistance test

Sample 3 (see 2.10.8.1)is subjected to the following test

Scratches are made across five pairs of conducting parts and the intervening separations at points where the separations will be subject to the maximum potential gradient during the tests.

The scratches are made by means of a hardened steel pin, the end of which has the form of a cone having a tip angle of 40°, its tip being rounded and polished, with a radius of 0.25 mm + 0.02 mm.

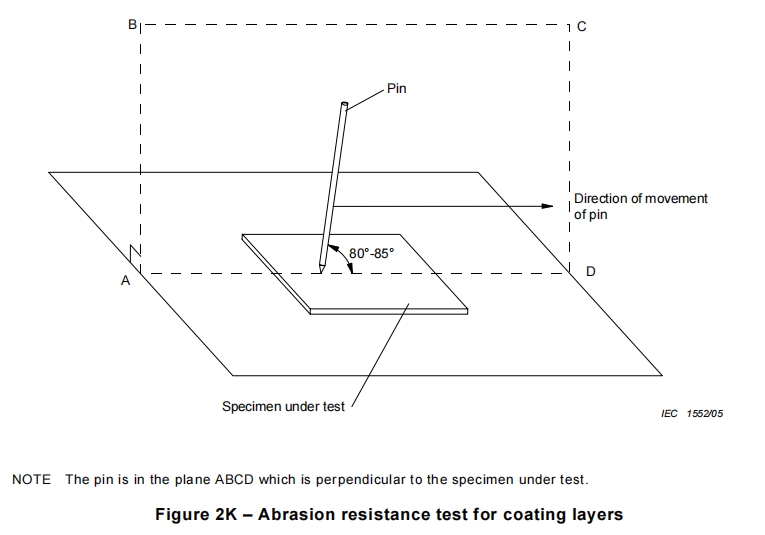

Scratches are made by drawing the pin along the surface in a plane perpendicular to the conductor edges at a speed of 20 mm/s + 5 mm/s as shown in Figure 2K. The pin is so loaded that the force exerted along its axis is 10 N+ 0.5 N. The scratches shall be at least 5 mm apart and at least 5 mm from the edge of the specimen.

After this test, the coating layer shall neither have loosened nor have been pierced, and it shall withstand an electric strength test as specified in 5.2.2 between conductors. In the case

of metal core printed boards, the substrate is one of the conductors.

------------------------------------------------------------------------------------------

-

IEC 60335 Clause 21.2 Abrasion resistance test

21.2 Accessible parts of solid insulation shall have sufficient strength to prevent penetration by sharp implements.

Compliance is checked by subjecting the insulation to the following test, unless the thickness of supplementary insulation is at least 1 mm and that of reinforced insulation is at least 2 mm.

The insulation is raised to the temperature measured during the test of Clause 11. The surface of the insulation is then scratched by means of a hardened steel pin, the end of which has the form of a cone with an angle of 40°, Its tin is rounded with a radius of 0.25 mm + 0.02 mm. The pin is held at an angle of 80'- 85 to the horizontal and loaded so that the force exerted along its axis is 10 N +0,5 N. The scratches are made by drawing the pin along the surface of the insulation at a speed of approximately 20 mm/s. Two parallel scratches are made. They are spaced sufficiently apart so that they are not affected by each other, their length covering approximately 25 % of the length of the insulation. Two similar scratches are made at 90"to the first pair without crossing them.

The test fingernail of Figure 7 is then applied to the scratched surface with a force of approximately 10 N. No further damage, such as separation of the material, shall occur. The insulation shall then withstand the electric strength test of 16.3.

The hardened steel pin is then applied perpendicularly with a force of 30 N +0.5 N to an unscratched part of the surface. The insulation shall then withstand the electric strength test of 16.3 with the pin still applied and used as one of the electrodes.

------------------------------------------------------------------------------------------

Summary:

The difference of the Abrasion resistance test between IEC 60335 AND IEC 60950 IS in the Yellow highlight section. the IEC 60335 has the requirement for the 30N high pressure test.

Technical parameters:

|

Input power supply

|

AC 220V/50Hz

|

|

Test station

|

One station

|

|

Control system

|

PLC + touch screen

|

|

Drive mode

|

Stepper motor drive

|

|

Scratching speed

|

0-25mm/s adjustable, can be preset

|

|

Scratching times

|

0-9999 times, it can be preset

|

|

Scratching distance

|

Approximately 25 % of the length of the insulation, can be preset

|

|

Test bench

|

Can be 90° rotated

|

|

Scratching pressure

|

10N±0.5N

|

|

Scratching pin

|

hardened steel pin, the end of which has the form of a cone with an angle of 40°. Its tip is rounded with a radius of 0,25 mm ± 0,02 mm

|

|

Scratching angle

|

80° to 85° to the horizontal

|

----------------------------------------------------------------------------

SHENZHEN BONAD INSTRUMENT CO,LTD provide this Scratch Resistance Test, if you have interest in this tester, please contact us freely.

Contact: Alice

Email:Alice@szbonad.com

Tel/Whataspp: 0086-13380391156

|